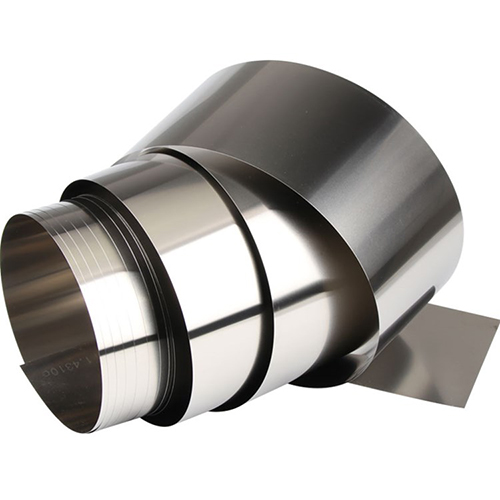

Mzere wa Titanium ndi Foil

• Mzere wa Tittanium ndi Zida Zojambula:Pure Titanium (CP) ndi Titanium alloy zojambulazo,Grade 1, Grade 2, 5, Grade 5, Grade 7 ndi Grade 9

• Mafomu: Mzere umodzi, koyilo, kapena pa spool.Slitting utumiki ulipo

• Makulidwe:makulidwe: ≥0.01mm : 20 ~ 1000mm, Utali: Monga Pempho

• Zoyenera:Zozizira zopindidwa(Y)~Zopiringizika zotentha(R)~Zopindika (M)~Zokhazikika

• Miyezo:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 etc.

• Mapulogalamu:Zamagetsi, mankhwala, mawotchi, magalasi, zodzikongoletsera, masewera, makina, plating zipangizo, zipangizo zachilengedwe, gofu ndi mwatsatanetsatane makina Machining mafakitale.

| Titanium Alloys Material Common Name | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Mzere wa Titanium ndi Foil:Timapereka makamaka titanium Strip ya Gr1, Gr2, Gr4;Pakuti titaniyamu aloyi zojambulazo, Ife makamaka kupereka Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 ndi magiredi ena, Iwo amapangidwa pamaziko a titaniyamu mbale ndi kugudubuzika zina ozizira;kupanga pepala la titaniyamu kumakhala kovuta kwambiri.Ulamuliro wa deformation umakhala wosamalitsa kwambiri pakupanga rolling.That imatha kudulidwa mosiyanasiyana malinga ndi zosowa za kasitomala, kufupikitsa kwambiri nthawi yobereka.

♦ Mankhwala a Titanium Strip Chemical ♦

| Gulu | Kupanga kwa Chemical, kulemera kwa zana (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Zinthu Zina Max.aliyense | Zinthu Zina Max.zonse | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Mzere wa Titanum AlloyMaonekedwe a thupi♦

| Gulu | Thupi katundu | |||||||

| Kulimba kwamakokedwe Min | Zokolola mphamvuMphindi (0.2%, kuchotsera) | Kuwonjezera pa 4D Mphindi (%) | Kuchepetsa Malo Mphindi (%) | Bend Test (Radius of Mandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm Mu makulidwe | 1.8-4.8mm mu makulidwe | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Mbali: ♦ ♦ ♦

•Kalasi 1: Titaniyamu Yoyera, mphamvu yochepa komanso ductility kwambiri.

•Gulu 2: Titaniyamu yoyera yomwe imagwiritsidwa ntchito kwambiri.Kuphatikiza kwabwino kwamphamvu

•Gulu 3: Titaniyamu yamphamvu kwambiri, yogwiritsidwa ntchito ngati mbale za Matrix mu zipolopolo ndi zosinthira kutentha kwa machubu

•Kalasi 5: Aloyi wa titaniyamu wopangidwa kwambiri.Mphamvu zapamwamba kwambiri.kukana kutentha kwakukulu.

•Kalasi 7: Kukana kwamphamvu kwa dzimbiri pakuchepetsa komanso kutulutsa ma oxidizing.

•Gulu 9: Mphamvu zapamwamba kwambiri komanso kukana dzimbiri.

•Gulu 12: Kukana kutentha kwabwino kuposa Titaniyamu yoyera.Mapulogalamu ngati a Giredi 7 ndi Gulu la 11.

•Kalasi 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy kuti apange opaleshoni yopangira opaleshoni.