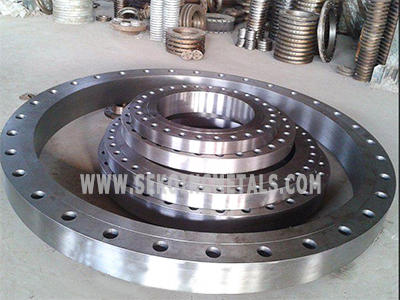

Inkoloy 825 Flange

Inkoloy 825 (W.Nr 2.4858) Flange

Zinthu za Flange :Inkoloy Alloy 825 (UNS N08825)

Mitundu ya Flange:Malinga makasitomala requirments

Tsiku lokatula :15-30 masiku

Nthawi Yolipira :T/T, L/C, Paypal, Ect

Sekoinc Metals Main kutulutsa ndi kupereka ma aloyi apadera Flanges, timavomereza dongosolo lachitsanzo

Chithunzi cha 825ndi The high nickel content imapereka aloyi yogwira mtima kupsinjika kwa dzimbiri kusweka.Kulimbana ndi dzimbiri ndikwabwino mumitundu yosiyanasiyana, monga sulfuric, phosphoric, nitric ndi organic acid, zitsulo zamchere monga sodium hydroxide, potaziyamu hydroxide ndi hydrochloric acid solution.

Kugwira ntchito kwapamwamba kwa Incoloy 825 kumawonetsedwa mu nyukiliya yoyaka moto yokhala ndi zida zosiyanasiyana zowononga, monga sulfuric acid, nitric acid ndi sodium hydroxide, zonse zimakonzedwa mu zida zomwezo.

| Aloyi | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 | Min. | 38.0 | 19.5 | 2.5 | 22.0 | - | - | - | - | 1.5 | 0.6 | - | |

| Max. | 46.0 | 23.5 | 3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 | 1.2 | 0.03 |

| Kuchulukana | 8.14g/cm³ |

| Malo osungunuka | 1370-1400 ℃ |

| Mkhalidwe | Kulimba kwamakokedwe Rm N/mm² | Zokolola mphamvu Rp 0. 2N/mm² | Elongation Monga% | Brinell kuuma HB |

| Yankho mankhwala | 550 | 220 | 30 | ≤200 |

• Mitundu ya Flange:

→ Welding mbale flange (PL) → Slip-on Neck Flange (SO)

→ Kuwotcherera khosi flange (WN) → Integral flange (IF)

→ Socket wowotcherera flange (SW) → Ulusi wowotcherera (Th)

→ Flange yolumikizana (LJF) → Blind flange (BL(s)

♦ Zida Zazikulu Za Flange Zomwe Timapanga

• Chitsulo chosapanga dzimbiri :Chithunzi cha ASTM A182

Gulu F304 / F304L, F316/ F316L, F310, F309, F317L, F321, F904L, F347

Duplex Stainless Steel: Gulu F44 / F45 / F51 / F53 / F55 / F61 / F60

• Nickel Aloyi: ASTM B472, ASTM B564, ASTM B160

Mtengo wa 400,Nickel 200, Inconel 825, Incoly 926, Inconel 601, Inconel 718

Hastelloy C276, Aloyi 31, Aloyi 20, Inconel 625, Inconel 600

• Titaniyamu Aloyi:Gr1/Gr2/Gr3/Gr4/GR5/Gr7/Gr9/Gr11/Gr12

♦ Miyezo:

ANSI B16.5 Class150,300,600,900,1500(WN,SO,BL,TH,LJ,SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

Inkoloy 825 Zopezeka mu Sekonic Metals

Chifukwa chiyani Inoloy 825 ?

825 alloy ndi mtundu wa aloyi waukadaulo waukadaulo, womwe umakhala ndi kukana kwa asidi ndi alkali pakuwotcha komanso kuchepetsa chilengedwe komanso kukana kupsinjika kwa kuphulika kwa nickel chifukwa cha kapangidwe kake ka nickel. asidi, phosphoric acid, nitric acid ndi organic acid, ku alkali, monga sodium hvdroxide, potaziyamu hvdroxide ndi hvdrochloric acid solution.Mawonekedwe apamwamba a 825 alloy akuwonetsa mu zida zowotcha za nyukiliya zamitundu yosiyanasiyana ya dzimbiri, monga sulfuric acid, nitric acid ndi sodium hvdroxide zonse zimagwiridwa ndi zida zomwezo.

•Kukaniza bwino kupsinjika kwa corosion kusweka.

•Kukaniza bwino kwa pitting ndi dzimbiri paming'alu

•Kukaniza kwabwino kwa okosijeni ndi asidi wopanda oxidizing.

•Good makina katundu kutentha firiji kapena to550 ℃

•Chitsimikizo chopangira mphamvu chotengera cha 450 ℃

Ntchito ya Inkoloy 825:

•Zigawo monga zotenthetsera zowotchera, akasinja, mabokosi, madengu ndi unyolo muzomera zokokera za sulfuric acid

•Zotenthetsera zoziziritsa kumadzi za m'nyanja, makina opangira mapaipi akunja;machubu ndi zigawo zina muutumiki wa gasi wowawasa

•Zotenthetsera kutentha, ma evaporators, scrubbers, mipope yoviika ndi zina pakupanga phosphoric acid.

•Zotenthetsera zoziziritsidwa ndi mpweya m'malo oyeretsera mafuta

•Kukonza chakudya

•Mankhwala chomera